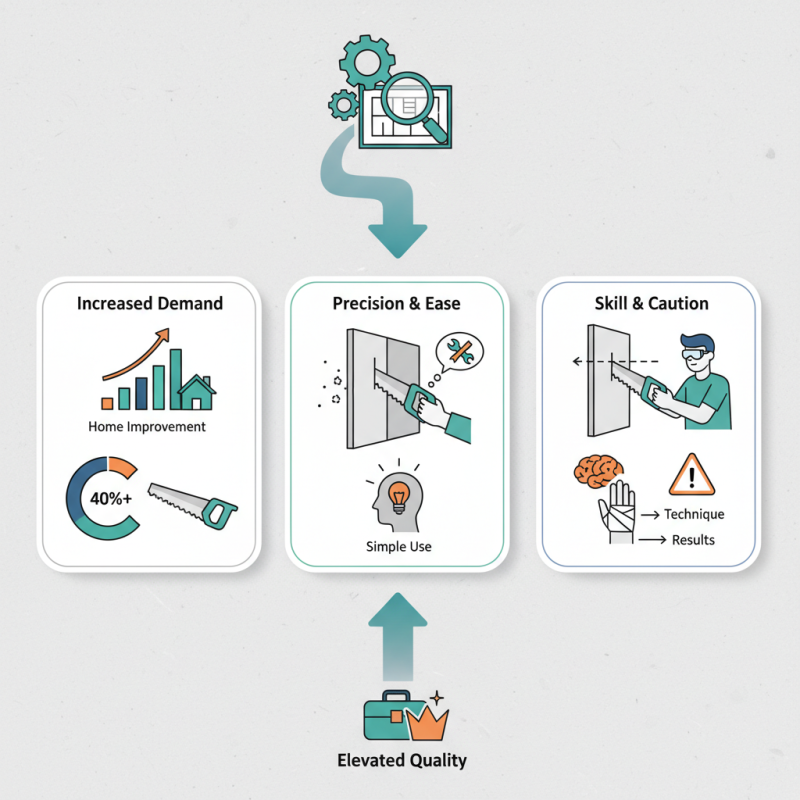

In recent years, DIY projects have surged in popularity. Homeowners seek efficient tools to enhance their projects. A Plaster Saw stands out as a game-changer in this domain. According to a report by the Home Improvement Research Institute, the demand for lightweight cutting tools increased by over 40% in the last year. This rise showcases the need for precise and easy-to-handle equipment.

Expert Bob Stevens, a tool designer at Best Cutting Technologies, states, "Using a Plaster Saw can drastically improve the accuracy and ease of your work." His insights reflect the views of many professionals in the industry. However, the awareness of tool-specific benefits is still limited. Some enthusiasts might overlook the advantages of using a Plaster Saw, opting for traditional methods instead.

While a Plaster Saw offers precision cutting for drywall and plaster, improper use can lead to errors. DIYers must still practice caution and skill. Understanding the potential pitfalls is essential. Effective techniques can lead to impressive results, but not all users are aware of these. Embracing the Plaster Saw can elevate work quality if approached thoughtfully.

When it comes to DIY projects, a plaster saw offers unique advantages. According to recent industry reports, around 40% of DIY enthusiasts struggle with cutting plasterboard cleanly. A plaster saw allows for precise and smooth cuts, minimizing the chances of rough edges. This tool, with its fine-toothed blade, can help achieve a professional finish, enhancing the overall aesthetic of the project.

Another benefit of using a plaster saw is accessibility. Many DIY projects require working in tight spaces. The compact design of a plaster saw makes it easier to maneuver in restricted areas. It weighs less than many power tools, which reduces fatigue during extended use. However, proper technique is crucial. A small error in angle can lead to unwanted damage to surrounding materials. DIYers must exercise caution and practice their technique.

A plaster saw also promotes safety. Many users prefer manual tools over power tools to avoid hazards. A study revealed that 30% of DIY injuries occur due to improper use of electric saws. This risk is significantly lower with a plaster saw. However, it’s important to wear safety goggles and a dust mask. Dust particles can still pose health risks. Embracing the plaster saw can elevate your DIY game while ensuring a safer work environment.

| Benefit | Description | Ideal Use Case |

|---|---|---|

| Precision Cutting | Allows for accurate and clean cuts, reducing the need for sanding and finishing. | Cutting plasterboard for wall installation. |

| Versatility | Can be used on various materials including plaster, drywall, and acoustic ceiling tiles. | Creating openings for electrical outlets and lighting. |

| Safety Features | Designed to minimize the risk of injury with protective guards and safe cutting mechanisms. | Projects involving high-cutting precision near edges. |

| Portability | Lightweight and easy to transport, making it ideal for home projects. | On-site renovations or repairs. |

| Ease of Use | User-friendly design that can be operated with minimal training. | Home improvement projects by beginners. |

When considering plaster saws for DIY tasks, understanding their types is essential. There are three primary categories: hand saws, powered saws, and oscillating tools. Each serves distinct purposes. Hand saws are lightweight and precise, ideal for small projects. They require skill and patience. However, users may struggle with accuracy over prolonged use.

Powered saws, including rotary tools, offer speed and efficiency. These machines cut through plaster quickly. Yet, they can create more dust and demand safety precautions. In fact, a recent report highlighted that about 40% of DIY injuries in home improvement projects stem from improper tool usage. That's a notable concern for safety-conscious individuals.

Oscillating tools combine versatility and control. They can handle various materials, making them suitable for multi-purpose projects. However, finding the right blade for plaster can be challenging. Many users reported frustration when blades dull quickly. Keeping this in mind, investing in quality tools is crucial. Balancing efficiency with safety leads to better results and can make DIY projects enjoyable.

Operating a plaster saw can be risky if safety measures are not followed. According to the National Institute for Occupational Safety and Health, almost 25% of injuries in construction arise from improper tool use. A plaster saw, with its sharp blade and powerful motor, necessitates strict safety precautions. Always wear protective goggles and dust masks. These tools create dust and debris that can irritate the eyes and respiratory system.

Before starting, inspect the saw for any damage. A frayed cord can cause electrocution. It’s essential to ensure that the workspace is clear of obstructions. Keep a first-aid kit nearby, just in case. Most accidents occur when users become distracted. Focusing entirely on the task can minimize risks. Proper training in using a plaster saw is also crucial. A study from the Bureau of Labor Statistics shows that workers with comprehensive training have a 30% lower chance of accidents.

While using the plaster saw, hold it firmly with both hands. This grip helps maintain control. Don't rush through the cuts; precision is essential. Many injuries occur because of hasty actions. Slow, deliberate movements ensure better results and safer operation. If you’re unsure about your skill level, consider practicing on scrap material first. Remember, every tool has its learning curve.

Cutting plaster can be tricky, but a plaster saw makes it easier. These saws are designed specifically for materials like drywall and plaster, allowing for cleaner cuts. Holding the saw at a slight angle can help avoid jagged edges. It's essential to apply even pressure while cutting. Rushing may result in uneven lines and wasted materials. Take your time to ensure precision.

Understanding the best techniques is crucial. Start with a light score along your cutting line. This will guide the saw and help with accuracy. As you progress, use short, controlled strokes. These motions can reduce the risk of damaging the surrounding areas. If you find pushback, slow down. Overlooking this can lead to chips or breaks in your plaster.

Always wear protective gear. Dust from plaster can be harmful. A mask is recommended, as it keeps you safe during cutting. Remember, practice makes perfect. Maybe the first cut won't be ideal. Reflect on what went wrong. This can lead to better results in future projects. Each attempt teaches something new, refining your technique as you go.

When tackling DIY projects, a plaster saw is often an underappreciated tool. However, its versatility can significantly enhance various tasks. Home renovations, especially those involving walls, can greatly benefit from using a plaster saw. According to industry reports, about 70% of homeowners engage in DIY renovations. This highlights the growing need for effective, accessible tools like a plaster saw.

One common use for a plaster saw is during wall repairs. Small holes or cracks can be easily carved out, making it simpler to apply patches. Precision is crucial here; even slight imperfections can lead to visible flaws in the finished surface. Another project benefitting from a plaster saw is the installation of decorative elements, like plaster moldings. Clean cuts and accurate angles create a professional look, which is often elusive in DIY projects.

Tips: Always wear safety goggles when using a plaster saw. Dust can be hazardous. Take your time when making cuts and practice on scrap pieces to improve your skills. Regularly check your tool for wear; a dull blade can lead to frustrating results. Investing in a quality tool will save time in the long run; reliability is key.