In the evolving landscape of electrical solutions, the "temp power box" stands out as a pivotal tool for managing temporary power needs. Expert John Smith, a leading voice in portable power solutions, emphasizes, "A temp power box bridges the gap between energy demand and availability." This statement highlights its crucial role in events, construction sites, and emergency scenarios.

A temp power box is not just a convenience; it is essential for maintaining productivity. During a festival, for instance, the proper setup of temp power boxes ensures vendors and lighting systems receive uninterrupted power. Yet, this system is often overlooked until a need arises. The intricacies of proper connection and safety can also lead to common operational challenges.

With a temporary power setup, it’s important to acknowledge potential pitfalls. Users may encounter issues like inadequate wattage or improper connections. These oversights can lead to frustrating delays. Reflecting on these experiences can improve future installations and enhance efficiency.

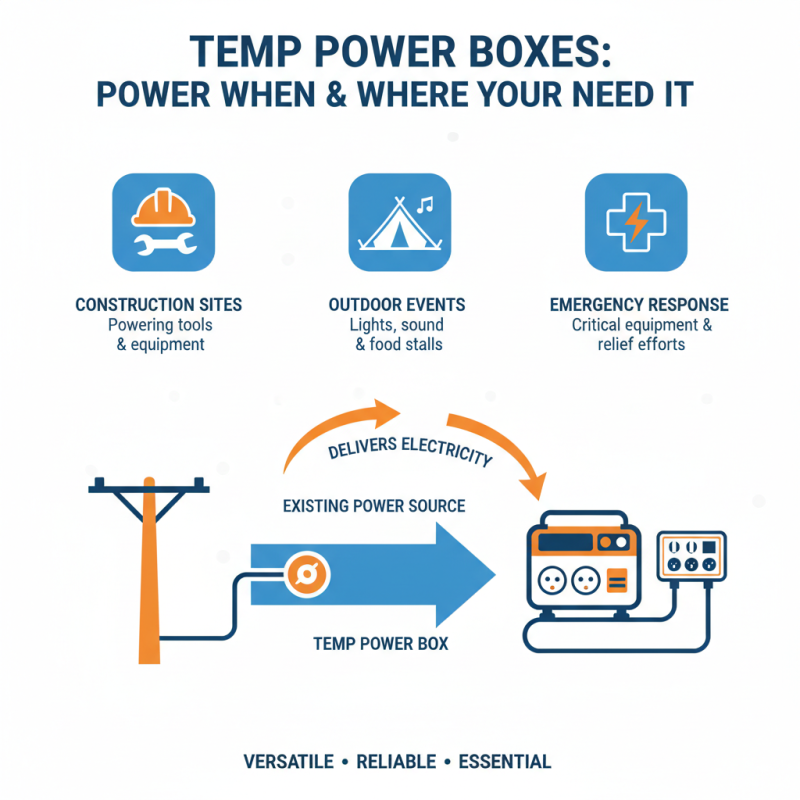

A temporary power box is a crucial tool in construction and outdoor events. It delivers electricity safely when the main power source isn't accessible. These boxes provide an efficient way to manage power needs, with circuits designed to handle various electrical loads.

Typically, temp power boxes can support multiple outlets for tools and appliances. They are rated based on amperage, with common sizes including 100 amps and 200 amps. According to industry reports, using a temporary power solution can reduce downtime by 30%. This efficiency is vital on busy job sites. Workers can maximize productivity without the hassle of external power sources.

Tips: Always inspect the temp power box before use. Look for any visible damage or wear. Ensure the ground fault circuit interrupters (GFCIs) are functional; they prevent electrical shocks. Additionally, proper grounding is essential for safety. Misconnections can lead to equipment failure or even accidents. Planning ensures you set up the temp power box correctly in advance. This small step can lead to better results in your projects.

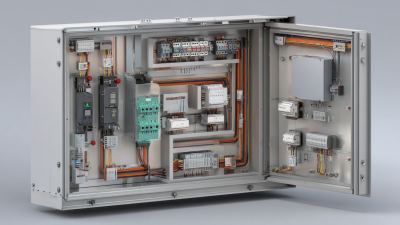

A temp power box is essential for temporary electrical needs. These boxes are commonly used in construction sites, events, or outdoor activities. Understanding the key components can help ensure smooth operation.

The main components include the power inlet and distribution panel. The power inlet connects to an external source. It allows safe power transfer. The distribution panel manages electricity flow to various outlets. This panel often features circuit breakers for added safety.

Cables and outlets are also crucial. Cables must be durable and rated for the power load. Outlets should be accessible and weatherproof for outdoor use. Many boxes include overload protection systems. However, users sometimes overlook the importance of grounding. Grounding can prevent electrical shocks but is often neglected. Reflecting on these details improves safety and efficiency in using temp power boxes.

| Component | Description | Function |

|---|---|---|

| Main Panel | The central unit that distributes power to various circuits. | Controls and redirects electricity to different loads. |

| Circuit Breakers | Safety devices that cut off power during overloads. | Protects the electrical system by preventing excess current. |

| Outlet Receptacles | Points where devices can be plugged in to access power. | Provides accessible power sources for equipment. |

| Transformers | Devices that change the voltage of electricity. | Customizes voltage levels for specific equipment requirements. |

| GFCI Outlets | Ground Fault Circuit Interrupters that protect against shock. | Enhances safety by cutting off power when a fault is detected. |

A temp power box, or temporary power distribution unit, is crucial for construction sites and events. It provides electrical power safely and efficiently during projects. Understanding how these boxes operate can prevent mishaps.

Temp power boxes connect to the main power supply, distributing electricity as needed. They convert high voltage electricity into usable, lower voltages. This ensures every tool or device receives the correct power. Many boxes feature circuit breakers for safety, reducing the risk of overload. According to industry reports, proper installation can reduce electrical failures by up to 70%.

Tips: Regularly check your temp power box for any signs of wear or damage. Proper maintenance is key.

When using a temp power box, ensure that all connections are secure. Loose wires can lead to electrical hazards. Knowledge of load calculations is vital. Oversights here can result in serious issues. Always remember, electrical safety should be your top priority.

Temp power boxes are versatile tools that provide temporary electrical power in various situations. They are commonly used at construction sites, outdoor events, and emergency response scenarios. By connecting to existing power sources, these boxes deliver electricity where and when it’s needed.

In construction, temp power boxes facilitate tools and machinery that operators rely on. They keep work moving forward even in remote locations. Outdoor events, such as concerts or festivals, utilize these boxes for lighting, sound systems, and food vendors. It’s crucial to ensure that all connections are secure and safe.

Tips: Always inspect the box before use. Check for damage or wear that could lead to hazards.

Emergency situations also benefit from temp power boxes. They can provide vital energy for equipment in disaster relief efforts, ensuring that aid can be delivered. However, placing the box in a secure location is essential to prevent theft or damage.

Tips: Keep a portable generator handy. It can serve as a backup power source if needed.

When using temporary power boxes, safety should be the top priority. These devices, while convenient, carry potential risks. According to the National Electrical Contractors Association (NECA), improper use contributes to significant electrical incidents. Inadequate grounding or overloaded circuits often lead to accidents. It’s crucial to assess power needs and ensure that the temp power box matches those specifications.

Avoid connections in wet or damp environments. Moisture can lead to short circuits or electrocution. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of weatherproof equipment. Temporary setups should not compromise on protection. Regular inspections can prevent hazards. A 2022 industry report found that 30% of construction site incidents stem from electrical issues.

Training workers on the safe use of temp power boxes is essential. Many accidents occur due to untrained personnel mishandling equipment. Clear signage and instructions can reduce this risk. In an era where 20% of electrical accidents result in serious injuries, it’s vital to foster a culture of safety. Even small oversights can have devastating consequences.