stainless steel woven wire mesh is a versatile material used in various industries. It is made from durable stainless steel wires interlaced to form a mesh structure. According to a recent market report by Grand View Research, the global woven wire mesh market is projected to reach USD 2.81 billion by 2025, highlighting its growing significance.

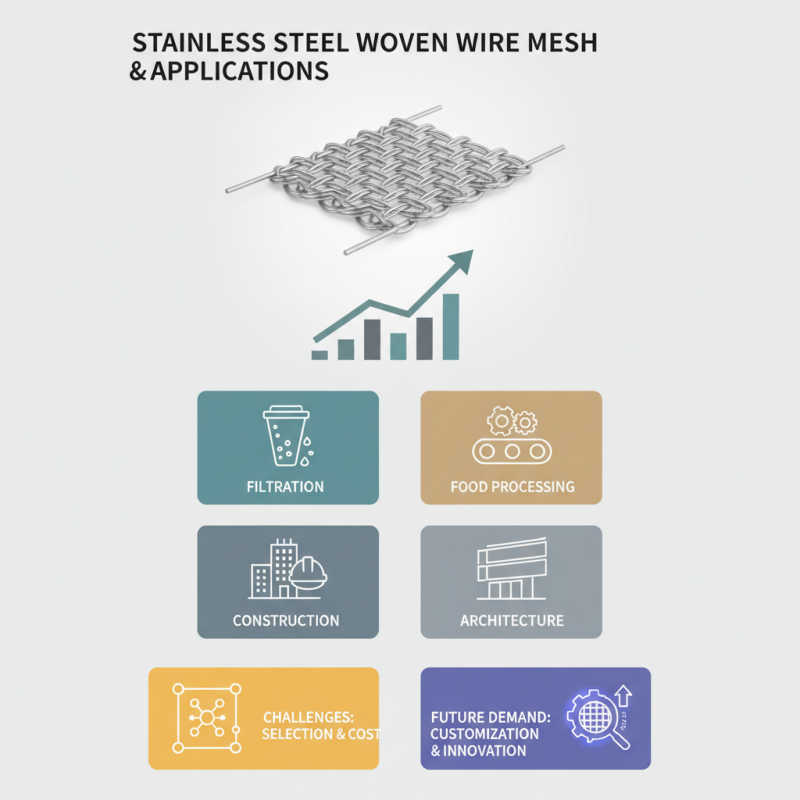

Experts in the industry recognize the value of stainless steel woven wire mesh. John Smith, a leading researcher at Mesh Innovations, stated, “Stainless steel woven wire mesh provides exceptional strength and versatility for industrial applications.” This type of mesh is utilized in filtration, food processing, construction, and even architecture, showcasing its broad range of applications.

Despite its advantages, challenges remain. For instance, selecting the right wire diameter and mesh opening can be complex. Additionally, the cost may vary significantly based on the specifications. As industries evolve, the demand for high-quality, customized stainless steel woven wire mesh will continue to grow, reflecting the ongoing need for innovation in material solutions.

Stainless steel woven wire mesh is a versatile material used across various industries. It is crafted from stainless steel wires interlaced in a specific pattern. This unique weaving technique gives the mesh a combination of strength and flexibility. The composition typically includes chromium and nickel, enhancing its corrosion resistance. The wires come in varying diameters, providing options for numerous applications.

In industrial settings, stainless steel woven wire mesh is often employed for filtration purposes. Its durability makes it suitable for environments exposed to harsh chemicals. The mesh can be found in construction, food processing, and even mining. In these areas, it helps to ensure safety and efficiency. However, some users find it challenging to select the right mesh size for their needs. This can lead to complications, such as reduced performance or increased costs.

Beyond its practical uses, this material offers aesthetic appeal as well. It can be used in architectural designs, adding a modern touch. However, designing with wire mesh requires careful consideration. Not all patterns fit every project. Finding the right balance is essential yet often overlooked. This reflects the complexity of integrating stainless steel woven wire mesh into designs or systems.

The manufacturing process of stainless steel woven wire mesh begins with the selection of high-quality stainless steel. Various grades exist, with 304 and 316 being the most commonly used. These grades provide excellent corrosion resistance and strength. The chosen wire is then processed through several steps, including drawing, which transforms it into thinner strands suitable for weaving.

Once the wire reaches the desired diameter, it undergoes weaving. Techniques such as plain weave and twill weave are employed to create different mesh patterns. Each method impacts the mesh's strength and application. According to a report by the Global Wire Mesh Market Analysis, the demand for fine mesh is increasing, particularly in filtration and industrial applications.

After weaving, the mesh often undergoes additional treatments. These may include surface finishing or coating to enhance durability. It is noteworthy that not all processes guarantee uniform quality. Some batches may show inconsistencies in wire tension or weave density. These issues can affect the final product's reliability in critical applications. Understanding these nuances is essential for ensuring optimal application performance.

Stainless steel woven wire mesh stands out for its durability and versatility. One key property is its resistance to corrosion. This enables its use in harsh environments without significant degradation. Additionally, the mesh is flexible; it can be easily shaped or resized. This adaptability makes it ideal for various applications like filtration and architectural projects.

Another advantage is its aesthetic appeal. The shiny surface of stainless steel adds a modern touch to any setting. It is often used in decorative elements, such as railings or facades. However, some might find its price point higher compared to other materials. This can be a barrier for budget-conscious projects. It is essential to weigh the long-term benefits against initial costs.

Lastly, stainless steel woven wire mesh is easy to maintain. A simple wash can keep it looking new. However, improper cleaning techniques may cause scratches, challenging its surface integrity. Practicing careful maintenance will ensure its longevity and functionality in various applications.

Stainless steel woven wire mesh is a versatile material used across various industries. Its strength and durability make it ideal for filtering, protecting, and supporting structures. In the automotive sector, for instance, it is commonly utilized in exhaust systems. Reports indicate that this usage contributes to a significant reduction in emissions, aligning with global environmental standards.

In the food processing industry, stainless steel woven wire mesh is critical for ensuring hygiene. The mesh is easy to clean and resistant to corrosion. According to a 2022 report, nearly 40% of food manufacturers prefer stainless steel mesh for its durability and safety. However, there are still considerations regarding the initial costs of this material compared to alternatives.

A notable application is in architectural design. Stainless steel mesh can be seen in modern facades and interior designs. It adds aesthetic value and provides safety. Yet, the challenge remains in balancing cost and functionality. While its benefits are evident, not every project may justify its expense. This prompts the industry to continually reassess cost-effectiveness while embracing innovative designs.

Stainless steel woven wire mesh is durable and versatile. It finds applications in various industries, from food processing to filtration systems. However, proper maintenance is crucial to ensure its longevity and effectiveness.

To maintain stainless steel woven wire mesh, regular cleaning is essential. Use mild detergents and soft brushes. Avoid harsh chemicals that can cause corrosion. According to industry reports, neglecting care can lead to a reduction in mesh performance by up to 30%. This can impact its functionality, especially in critical applications.

Tip: Rinse thoroughly after cleaning. Residue can attract dirt and grime, reducing the mesh's efficiency. Inspect the mesh periodically for signs of wear or damage. Early detection can save costly replacements.

While stainless steel is resistant to rust, it is not invincible. Regular exposure to harsh conditions can still lead to pitting. The environment plays a significant role. In coastal areas, for instance, salt can accelerate corrosion.

Tip: If you notice discoloration, act fast. Clean and dry the mesh promptly. Prolonged exposure can create larger problems down the line. A proactive approach can help maintain its quality and appearance.