When embarking on a welding project, one of the critical components that can significantly impact performance and safety is the choice of welding cable connectors. These connectors are essential for establishing a reliable electrical connection between the welder and the workpiece, as well as at various junctions within the system. Selecting the right welding cable connectors means considering factors such as material compatibility, voltage ratings, and environmental conditions. The correct connectors not only ensure efficient current transmission but also enhance the overall durability and reliability of the welding setup.

In this guide, we will delve into the key considerations for choosing welding cable connectors tailored to your specific project requirements. Whether you are a seasoned welder looking to enhance your toolkit or a beginner navigating the complexities of welding gear, understanding the nuances of connector selection is vital. By evaluating aspects such as connector types, sizes, and installation techniques, you can make informed decisions that will contribute to the success of your welding tasks while ensuring safety and longevity. Let us explore the essential criteria you must consider to choose the right welding cable connectors effectively.

Welding cable connectors play a crucial role in ensuring optimal performance and safety during welding operations. Understanding the different types of connectors available is essential for selecting the right one for your project. Common types include lug connectors, which provide sturdy connections for heavy-duty use, and twist-lock connectors, designed for quick and secure attachments. Additionally, some connectors feature a universal design, making them compatible with various cable sizes and equipment types.

When choosing welding cable connectors, it's important to consider the specific application and environment. For instance, connectors used in outdoor or industrial settings should be rated for weather resistance and durability. Likewise, high-amperage projects necessitate connectors that can handle larger electrical loads without overheating. Familiarizing yourself with the different materials, such as copper and aluminum, as well as their respective advantages, will further aid in making an informed choice that enhances both performance and safety in your welding endeavors.

When selecting welding cable connectors, two critical factors must be considered: the material used in the connectors and their current rating. The choice of material significantly influences not only the performance but also the durability of the connectors. Common materials include copper and aluminum, each offering unique benefits. Copper connectors are known for their excellent conductivity and strength, making them ideal for high-demand environments, while aluminum connectors are lighter and often more cost-effective, though they may necessitate regular maintenance to ensure optimal performance.

Equally important is the current rating, which determines the maximum load the connectors can handle without overheating or failing. Selecting connectors with an appropriate current rating is essential for maintaining safety and efficiency in welding applications. It's advisable to consult with manufacturers or industry guidelines to ensure that chosen connectors can reliably support the demands of specific projects, particularly in high-current scenarios. Engaging with advancements such as machine learning predictions can also aid in making informed decisions regarding connector capabilities and performance under various load conditions.

| Connector Type | Material | Current Rating (Amps) | Voltage Rating (Volts) | Recommended Application |

|---|---|---|---|---|

| MIG Connector | Copper | 200 | 30 | MIG Welding |

| TIG Connector | Brass | 150 | 25 | TIG Welding |

| Stick Connector | Aluminum | 300 | 40 | Stick Welding |

| Multi-Process Connector | Copper Alloy | 250 | 35 | Multi-Process Welding |

When selecting welding cable connectors for your project, it's crucial to adhere to

industry standards to ensure safety and efficiency.

According to the American National Standards Institute (ANSI), the proper connector must match

the cable gauge to prevent overheating and ensure a secure electrical connection. A recent

industry report noted that improper connections could lead to failures in up to 30% of welding

equipment, causing both safety hazards and costly downtime.

Tips: Always verify the voltage and current ratings of your connectors to

ensure compatibility with your welding equipment. Utilizing connectors rated for higher amperage than your project

requires can provide an added margin of safety and minimize wear.

Additionally, the International Electrotechnical Commission (IEC) emphasizes that

materials used in connectors play a vital role in performance. Copper is the

preferred choice for its excellent conductivity, while corrosion-resistant coatings can extend the life of connectors.

A flawed connection can compromise weld quality and negatively impact overall project results.

Tips: Consider investing in high-quality connectors that meet or exceed

IEC standards to ensure reliability. Regular maintenance and inspections can help identify wear or damage

before it becomes a significant issue, safeguarding your project from unexpected disruptions.

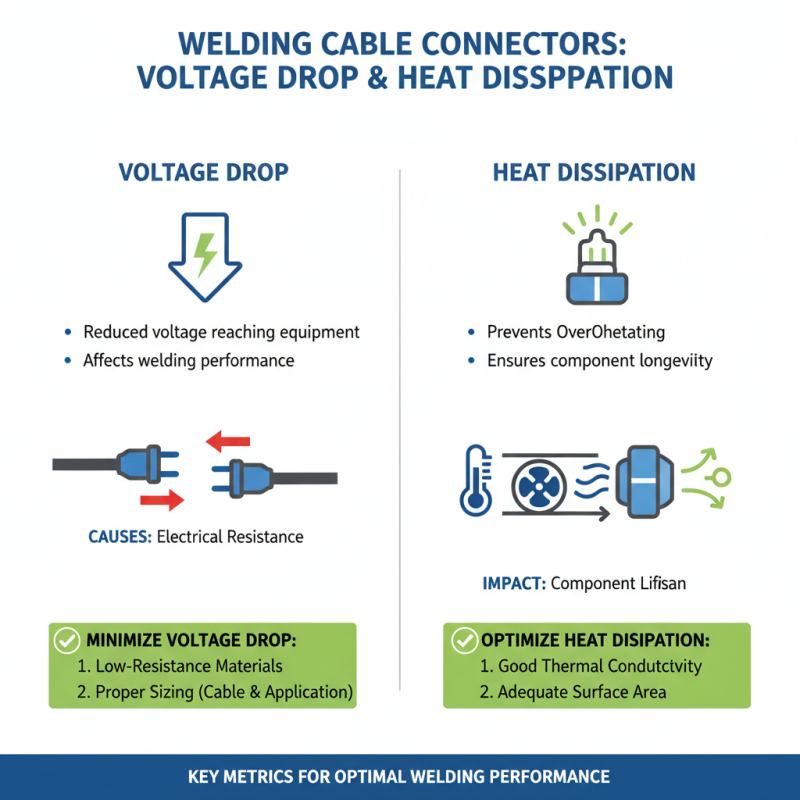

When selecting welding cable connectors, understanding the performance metrics of voltage drop and heat dissipation is crucial. Voltage drop occurs when electrical resistance in the connectors prevents the full voltage from reaching the welding equipment, which can significantly affect performance. To minimize voltage drop, choose connectors with low resistance materials and ensure that the connectors are properly sized for the cable and application.

Heat dissipation is another vital factor in connector selection. Excessive heat can lead to premature connector failure, reduced efficiency, and safety hazards. Look for connectors designed with features that enhance heat dissipation, such as those incorporating heat-resistant materials and improved airflow. Regularly inspect the connections for signs of overheating, such as discoloration or melting.

**Tips:** Ensure that you regularly check the specifications of connectors and select those that match your project’s voltage and current requirements. Additionally, investing in high-quality connectors with proper ratings can prevent costly downtime and enhance the longevity of your welding setup.

When dealing with welding cable connectors, proper installation and maintenance are crucial to ensuring safety and optimizing performance. According to the American Welding Society, improper connections can lead to increased resistance, resulting in overheating and potential failures. It's essential to regularly inspect connectors for signs of wear or damage, as this can severely affect the integrity of the electrical flow and overall welding quality.

**Tips:** Always ensure that connectors are clean and free of contaminants before installation. Using a specialized connector cleaner can significantly enhance conductivity and reduce the risk of arcing during operation. Additionally, refer to the manufacturer's specifications regarding torque settings for secure attachments without over-tightening, which could damage the connectors.

To extend the life of your welding connectors, implement a routine maintenance schedule. The National Electrical Code recommends checking the connections at least once every six months or more frequently in high-use environments. This should include a thorough inspection of cable insulation, ensuring there are no frayed wires or exposed metal. Keeping an updated log of maintenance activities can help identify patterns or recurring issues that may need more extensive solutions.